Meeting each client's individual requirements means understanding each individual part so that the correct decision can be made during the processing operation. Safety inspections are mandatory in the case of safety related components!

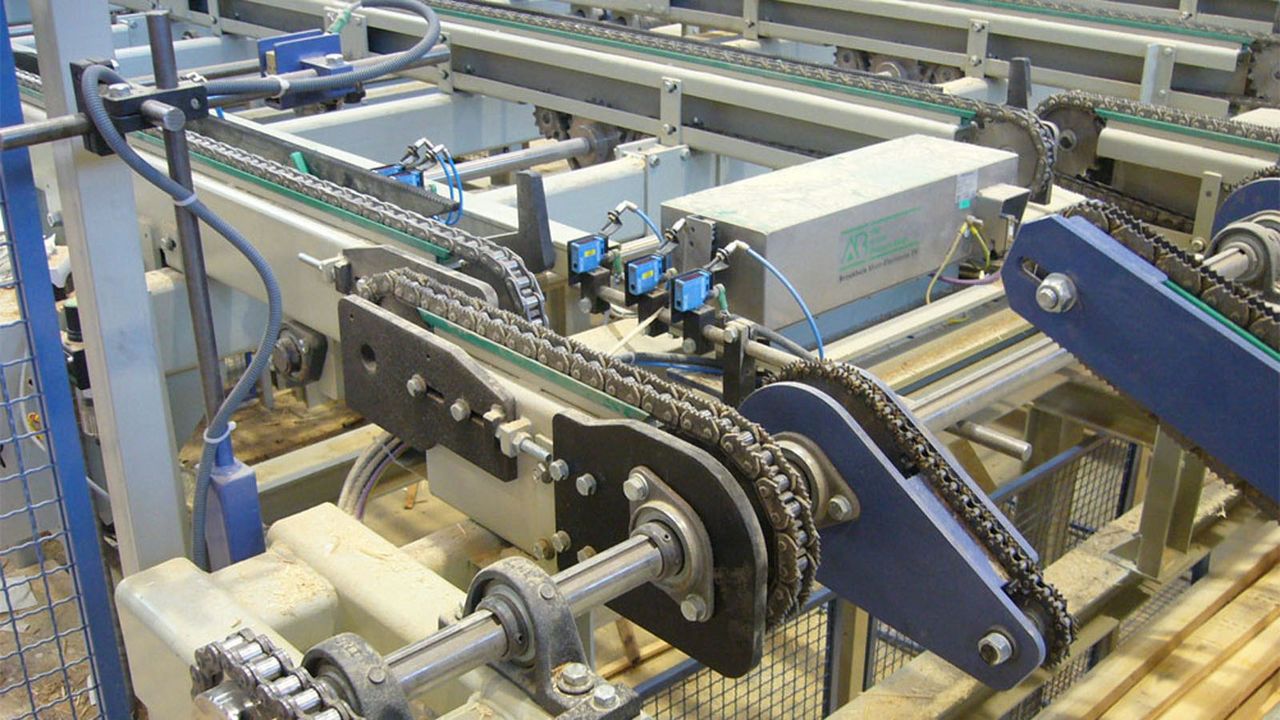

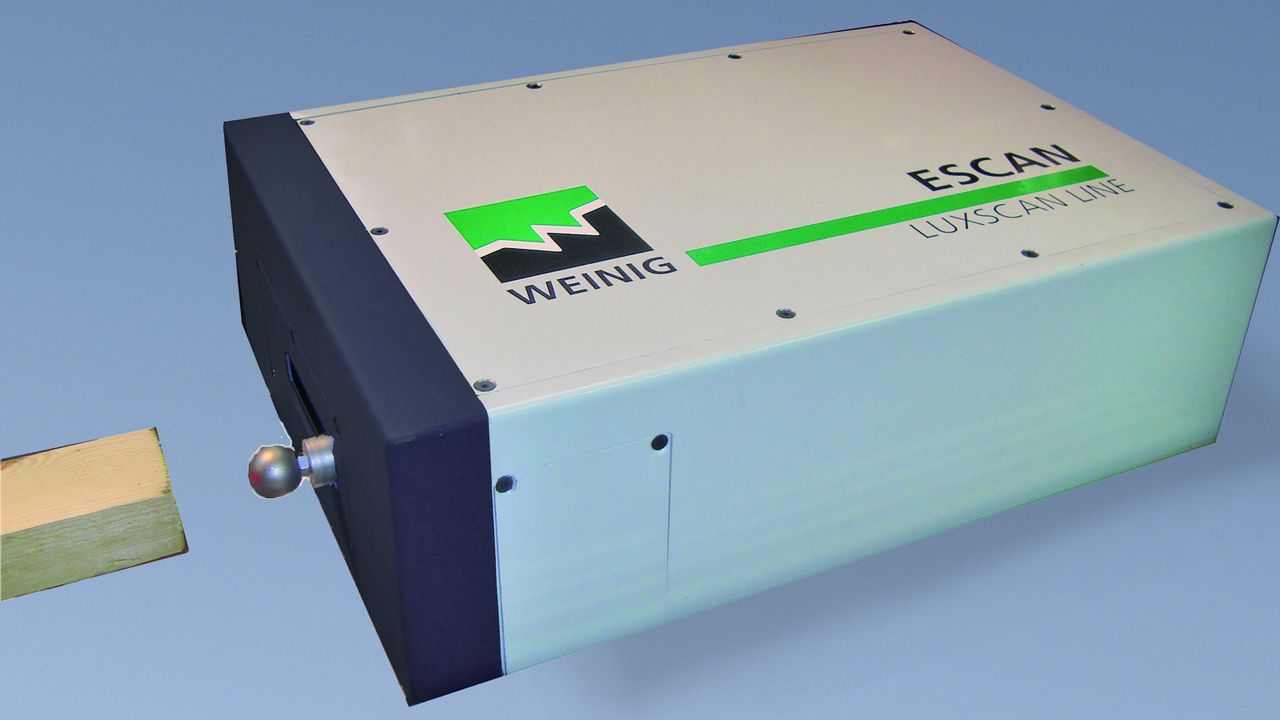

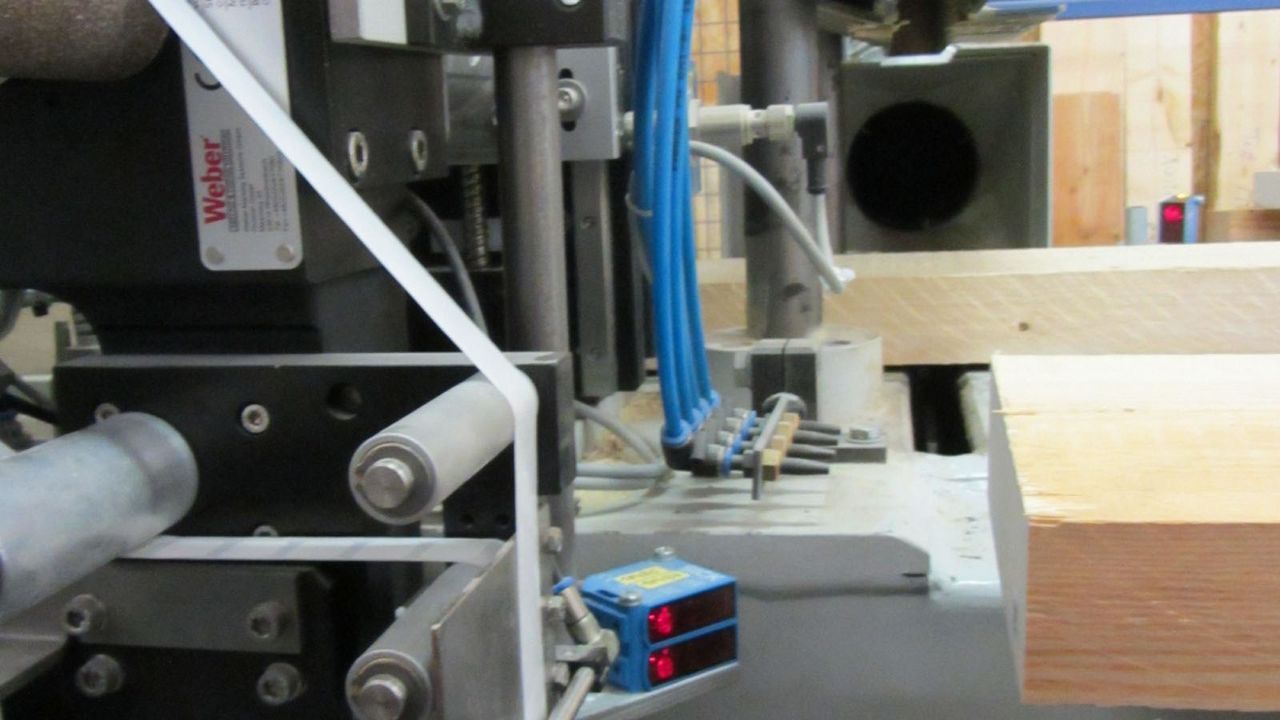

Part specific inspection due to size, shape, moisture or other requirement can be done using automatic sensors and based on known values. Actions can then be carried out if needed, e.g. rotating, sorting out, cutting or marking of the part.

Component specific application of marks, labels etc. can be made if needed.