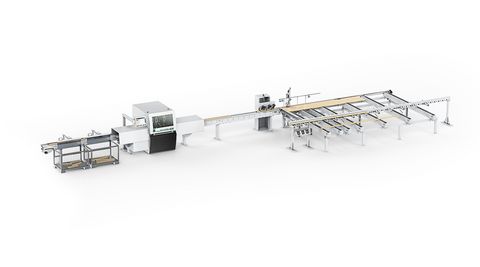

OptiCut 450 XL optimizing cross-cut saw: Reliable when cutting extremely large cross-sections

The OptiCut 450 XL is the machine in the OptiCut 450 series for large and oversized wood cross-sections. Equipped with individually suspended and extra wide feed rollers, this optimizing cross-cut saw generates high torque and transfers it to large and heavy boards. Its strong overhead drive rollers follow the wood contour for consistent power transmission and maximum grip, enabling precise positioning. The standard configuration comprises a saw blade with a diameter of 700 mm for processing cross-sections up to 430 x 25 mm or 235 x 200 mm. Despite the large cross-sections, the machine offers high cutting performance and length accuracy, as this model variant also features the non-driven measuring wheel in front of the saw blade and a pneumatically controlled waste gate as standard.

Of course, the OptiCut 450 XL also has infeed, marking and sorting solution options available – designed specifically for large and heavy boards - because the optimizing cross-cut saws are designed according to a modular system, with which you are well equipped for the future.

Different requirements - different prices

The price of a WEINIG machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your WEINIG expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local WEINIG expert will be happy to discuss all further details with you.

The WEINIG OptiCut 450 XL provides

- Robust machine concept for extremely large cross-sections

- Three extra wide driven overhead feed rollers follow the wood contour

- Pneumatic saw stroke

- Cutting of cross-sections up to 430 x 25 mm or 235 x 200 mm is possible

- Integrated waste gate as standard

- Saw blade diameter 700 mm

- Measuring wheel in front of saw blade

- Min. fixed length behind saw blade: 300 mm

- Cutting tolerance ± 1.0 mm to 1000 mm length

Technical Details

Everything at a glance

The OptiCom Pro operator interface is available in two sizes - 15' and 18'. The modern industrial TFT screen convinces above all by its simple and intuitive operation, which does not require any special PC knowledge. The pressure-sensitive touch screen can be easily operated with gloves and is also protected against splash water and dust. With the OptiCom Pro, the advantages of the user interface come into their own. By displaying the toolboxes, the operator can display additional information or can access numerous production, machine and service functions directly. To display the work area at maximum size, the toolboxes can also be completely hidden. This enables better readability, especially from a greater distance.

Reliability and safety as standard

The OptiCut offers the safest solutions for reliable and trouble-free production even in the standard version – with full capacity utilization of the saws. Machine components, such as the intelligently controlled waste gate, which is precisely harmonized with the performance of the cross-cut saw, ensure smooth production. With the help of the waste gate, the waste parts are reliably separated from the OK parts immediately after cutting, avoiding problems with sorting and further processing. The multi-stage system also allows longer waste parts to be directly discharged – avoiding additional stages that impact performance.

Secure workpiece guidance

From the marker table to sorting, the OptiCut guarantees continuous and secure workpiece guidance. For example, inside the cross-cut saw, a continuous fence ensures a clean and exact alignment and a right-angled cut of the workpieces.

Options for extension

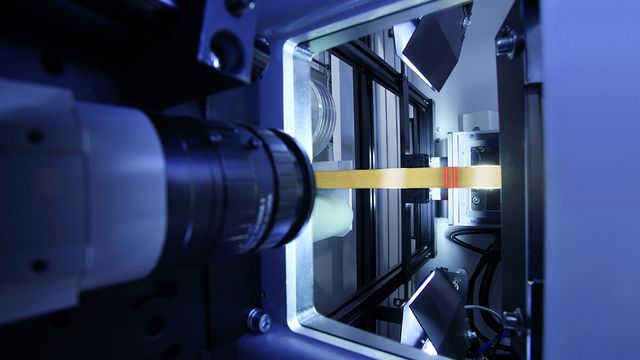

WEINIG scanner systems

Workpiece properties can be detected fully automatically and during production. Cutting is then performed automatically based on the data obtained.

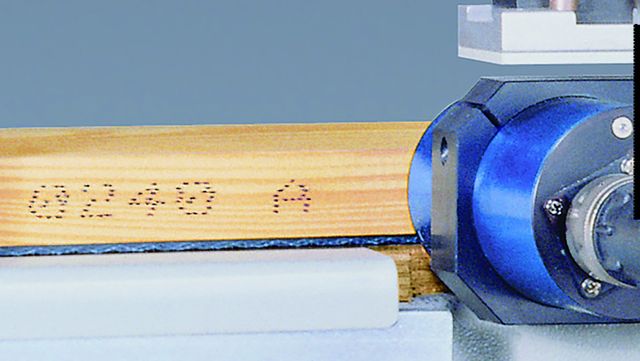

Workpiece marking

Thanks to workpiece marking, part allocation can be significantly simplified. The marking can be adapted individually.

OptiCut Stacker

When producing preferred lengths, the OptiCut Stacker forms a neat stack, adding stack slats between the layers if desired.

References

Further information

Brochures

Simple, fast and sustainable: more details in a downloadable PDF document.

Weinig OptiCut 450 series brochure (PDF, 11 MB)