Whether width/lengthwise cutting, scanner technology, optimization or gluing presses: WEINIG offers more. Let's take efficiency for example.

The best possible timber yield gives you better profitability in your company. That is something that cannot start soon enough in the production process. Cutting/gluing is the first step in every solid wood process and as such the “foundation” of efficient, modern production.

WEINIG offers a comprehensive portfolio of products and solutions in this area: from fixed or flexible width cutting to high-performance cutting to cross-cutting and gluing presses. Our machines work even more efficiently in combination with our latest scanner technology.

This means that from WEINIG you can obtain everything your need to make your production more efficient and economic from one source. And everything works in perfect harmony.

WEINIG products and solutions for cutting/gluing

WEINIG UniRip

Multi-blade rip saw with Quickfix.

- Perfect cut quality

- Short setup times

- Quickfix

- Easy to operate

- Low space requirements, compact design

WEINIG VarioRip

Multi-blade rip saw with up to 2 adjustable saw blades

- Perfect cut quality

- Up to 2 automatically adjustable saw blades

- Quickfix

- Short setup times

- Easy to operate

WEINIG ProfiRip series

High-performance multi-blade rip saw for all requirements.

- High performance potential

- Maximum stability and productivity — even with extreme loads

- Glueable cut

- Outstanding user-friendliness

- SafetyPlus anti kick-back device

WEINIG FlexiRip series

The longitudinal circular saw for flexible cutting in operations from the small workshop to industrial series production.

- Efficient and powerful ripping

- Optimum material yield

- Comprehensive safety concept

- Can be integrated in pre-cutting systems

- Innovative mechanical engineering

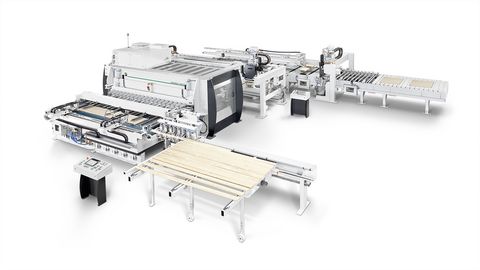

WEINIG CombiScan Sense series

Maximum performance and flexibility

- Fast return on investment

- Optimization of your products by value, utilization or production objective

- Extensive statistical functions in real time

- Compatible with all high-performance optimizing cross-cut saws, high-performance rip saws and sorting systems

- Optional processing of random width boards in a single production run

WEINIG EasyScan+ series

High performance with low investment - the new mid-range scanner from WEINIG

- Fast return on investment

- Optimization of your products by value, yield or production requirements

- Extensive real time statistics

- Compatible with all high-performance optimizing cross-cut saws.

- Optionally upgradeable sensor concepts (moisture measurement, shape measurement and much more)

WEINIG EasyScan & EasyScan Lite

The most profitable solution for wood optimization

Detail page EasyScan / EasyScan LiteWEINIG EasyScan RT series

The most profitable solution for wood optimization

- High productivity thanks to automated defect detection

- Reduced labor costs, since labor-intensive manual marking is dispensed with

- Increased recovery since the detection accuracy of the scanner is far superior to manual marking

- More flexible production since many different qualities and products can be produced at the same time

- Increased quality of end products

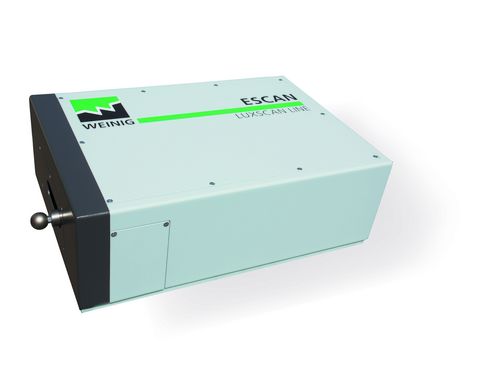

WEINIG EScan series

A new dimension for sorting by strength

- Up to 180 boards / minute

- Dynamic E-module measurement via laser interferometer

- Density measurement via dynamic weighing and dimension measurement

- Measurement during throughout feed (board does not have to be stopped for measurement)

- Easily integrated into existing production lines

WEINIG VarioSplit 900

Flexible band resaws for all woodworkers and wood processors with high demands in terms of saw cuts and service life.

- Solid and robust construction

- Bevel-cut device

- Easily adjustable and exchangeable saw blade guidance

- Frequency-controlled feed drive

- Simple and easy to adjust

WEINIG ProfiSplit 1100

The robust and modern band resaw as a single or twin band saw with a feed speed up to 80 m/min.

- Reliable and durable due to its robust construction

- Optimum material yield thanks to the center cut device

- Maximum productivity with feed speeds up to 80 m/min

- Flexibility due to the freely selectable limit stop side

- Minimum setup times and maximum variability thanks to saw units that can be positioned on both sides (TWIN)

WEINIG PowerSplit 1250

The band resaw as a single or twin band saw with a feed speed up to 150 m/min.

- Reliable and durable due to its robust construction

- Optimum material yield thanks to the center cut device

- Maximum productivity with feed speeds up to 150 m/min

- Flexibility due to the freely selectable limit stop side

- Minimum setup times and maximum variability thanks to saw units that can be positioned on both sides (TWIN, optional)

WEINIG OptiCut 200 series

Strong concept for profitable, high-performance cross-cutting

Detail page OptiCut 200 seriesWEINIG OptiCut 450 series

Optimizing cross-cut saws – built for maximum dynamism and performance with every cut.

Detail page OptiCut 450 seriesWEINIG OptiCut S 90 series

Optimizing cross-cut saws with positioning pusher: As universal and diverse as the requirements of your customers

Detail page OptiCut S 90 seriesWEINIG ProfiPress L II

The compact high-frequency gluing press for industry and trade.

- Multiplication of the daily capacity compared to manual gluing

- Extremely efficient input of high-frequency energy in the glue joint.

- Extremely user-friendly and maximum flexibility

- Mechanization and automation solutions are available as options.

- The best gluing and panel quality

WEINIG ProfiPress T

Perfectly adjusted, the upper mid-range

- Efficient even with small batch sizes

- Unlimited panel width possible

- Optimum machine utilization at all times as a result of a system that is not dependent on width

- Low post-processing as a result of minimum additional sanding

- Modular combinations possible - even after purchase!

WEINIG ProfiPress C

The very best. Non-stop high-performance

- Very high performance potential

- Perfect surface quality

- Maximum precision of machine and end product

- Convenient and user-friendly

- Best integration into existing, productivity-enhancing WEINIG system solutions

References for cutting/gluing

The ProfiPress L II impressed the Geschützten Werkstätte Integrative Betriebe Tirol GmbH with its work safety and simple operation.

“85% of our employees have a physical limitation, a mental disability or a learning difficulty, therefore it is extremely important to have simple operation!”, explains Georg Hechenblaickner, Marketing and Sales Manager of the Geschützten Werkstätte Tirol. “The most important thing for us was to keep the panel production flexible. It was also important to be efficient and to have process reliability, this is possible with the ProfiPress from Dimter!”